What is PU Coating ?

Polyurethane (PU) coating is a widely used finishing technique that enhances fabric performance, making it waterproof, durable, and resistant to harsh environmental conditions. This technology is extensively applied in outdoor clothing, such as windbreakers, rain jackets, and mountaineering gear, ensuring that wearers remain protected from wind, rain, and cold temperatures.

Today, leading fabric manufacturers such as fabrics-fty.com and textile-fty.com produce high-quality PU-coated fabrics tailored for outdoor and industrial applications. This article explores what PU coating is, its advantages, and how it is used in outdoor apparel and other industries.

1. What is PU Coating?

PU coating is a layer of polyurethane applied to fabric to improve its functionality. It creates a protective barrier that enhances water resistance, windproofing, and durability while maintaining flexibility and breathability. The coating is applied to materials such as polyester, nylon, or cotton through a specialized process, making them ideal for extreme weather conditions.

The thickness and type of PU coating can vary depending on the desired performance. Some fabrics have a thin PU layer for basic water resistance, while others have multiple layers to create completely waterproof and windproof textiles.

2. How PU Coating is Applied to Fabrics

The PU coating process involves several key steps to ensure durability and performance:

1.Fabric Preparation: The base material (polyester, nylon, or cotton) is pre-treated to remove impurities.

2.Coating Application: A liquid polyurethane solution is applied using a roller, spray, or lamination technique.

3.Curing and Drying: The coated fabric is heated to solidify the PU layer, ensuring strong adhesion.

4.Finishing Treatments: Additional treatments such as anti-static, flame retardant, or UV protection may be applied.

3. Advantages of PU Coating in Outdoor Apparel

PU-coated fabrics offer several benefits, making them a popular choice for outdoor wear and protective gear.

A. Waterproof and Windproof Properties

•PU coating creates a water-resistant barrier, preventing rain from penetrating the fabric.

•It enhances wind resistance, making it ideal for outdoor jackets, windbreakers, and raincoats.

B. Lightweight and Flexible

•Unlike heavy rubberized coatings, PU coating remains lightweight and flexible, ensuring comfort and ease of movement.

•It allows for easy packing, making it perfect for travel and outdoor adventures.

C. Breathability

•PU-coated fabrics are designed to allow moisture vapor to escape, preventing overheating and sweat buildup.

•Ideal for active outdoor wear such as hiking and running jackets.

D. Durability and Abrasion Resistance

•PU coatings increase fabric strength, making garments resistant to wear and tear.

•Essential for rugged outdoor conditions, ensuring longevity and reliability.

E. Chemical and Stain Resistance

•Provides protection against oils, dirt, and chemical exposure, making cleaning easier.

•Commonly used in industrial and military applications.

F. Versatile and Cost-Effective

•PU coating can be applied to various fabrics, including polyester, nylon, and cotton.

•More affordable than other waterproofing treatments, making it widely used in mass production.

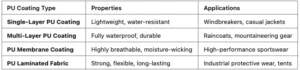

4. Types of PU Coatings and Their Uses

There are different types of PU coatings, each designed for specific applications.

5. Applications of PU Coated Fabrics in Outdoor Apparel

Due to its outstanding properties, PU-coated fabric is widely used in outdoor clothing and accessories.

A. Windbreakers and Rain Jackets

•PU-coated polyester and nylon fabrics provide essential protection against wind and rain.

•Lightweight and packable designs make them ideal for travelers and outdoor enthusiasts.

B. Mountaineering and Hiking Gear

•High-performance jackets and pants use PU membranes for breathability and waterproofing.

•Ensures protection in extreme weather conditions such as heavy rain and snow.

C. Ski and Snowboarding Apparel

•PU-coated fabrics enhance insulation and moisture resistance in winter sportswear.

•Keeps wearers warm and dry in snowy environments.

D. Outdoor Tents and Sleeping Bags

•PU-coated materials are used for waterproof tents and sleeping bags.

•Ensures comfort and protection in outdoor camping conditions.

E. Workwear and Protective Clothing

•PU-coated fabrics provide chemical and stain resistance for industrial and medical applications.

•Commonly used in lab coats, aprons, and firefighting gear.

F. Footwear and Accessories

•PU-coated materials are used in waterproof shoes, gloves, and backpacks.

•Provides extra protection against moisture and dirt.

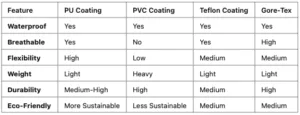

6. PU Coating vs. Other Waterproofing Technologies

PU coating offers a balance between affordability, durability, and performance, making it an ideal choice for outdoor apparel.

7. Caring for PU-Coated Fabrics

To maintain the quality and longevity of PU-coated garments:

• Wash in cold water with mild detergent to avoid degrading the coating.

•Avoid fabric softeners and bleach as they can break down the PU layer.

• Air dry or tumble dry on low heat to preserve flexibility.

•Reapply water-repellent sprays if waterproofing diminishes over time.

Conclusion

PU coating is an essential textile technology that enhances fabric performance for outdoor and industrial applications. Its waterproof, windproof, and breathable properties make it ideal for high-performance outdoor wear such as rain jackets, windbreakers, and hiking gear. Leading manufacturers like fabrics-fty.com and textile-fty.com continue to develop high-quality PU-coated fabrics, ensuring durability and functionality in various industries.

#PUCoating #WaterproofFabric #OutdoorGear #TechnicalTextiles #PUJacket #fabricsfty #textilefty #BreathableFabric #WindproofTextile #Rainwear