Interwoven fabric, also known as blended or hybrid fabric, is a textile created by weaving different types of fibers together to achieve enhanced properties. By combining materials like polyester (PET), cotton, nylon (PA), and spandex, manufacturers can create fabrics that offer improved durability, breathability, elasticity, and texture.

Common interwoven fabrics include poly-cotton (polyester-cotton), nylon-cotton, and polyester-nylon-cotton blends, which are widely used in various applications such as jackets, casual wear, outdoor clothing, and workwear. These fabrics are known for their high strength, comfort, and resistance to wear and tear, making them ideal for garments that require a balance of performance and aesthetics.

Top manufacturers like fabrics-fty.com and textile-fty.com specialize in producing high-quality interwoven fabrics, including ultra-fine denier materials that offer superior texture and function.

This article explores the characteristics, benefits, and applications of interwoven fabrics, along with their manufacturing process and industry uses.

1. What is Interwoven Fabric?

Interwoven fabric is produced by combining different fibers in the weaving process to create a textile with enhanced performance and unique texture. Unlike blended fabrics, which mix fibers at the yarn stage, interwoven fabrics are created by weaving warp and weft threads of different fiber types together.

The result is a fabric that retains the best properties of each material, offering strength, softness, elasticity, water resistance, or breathability, depending on the fiber combination used.

2. How is Interwoven Fabric Manufactured?

The production of interwoven fabric follows a structured process:

1.Material Selection: The choice of fibers depends on the desired characteristics of the final fabric (e.g., polyester for durability, cotton for softness, nylon for strength).

2. Warp and Weft Preparation: Different fiber types are arranged in the warp (vertical) and weft (horizontal) directions for weaving.

3.Weaving Process: The fibers are interwoven using techniques such as plain weave, twill weave, or satin weave to create the desired texture and strength.

4. Finishing Treatments: Additional processes like dyeing, coating, calendering, or waterproof treatment are applied to improve functionality.

3. Types of Interwoven Fabrics

A. Polyester-Cotton Fabric (Poly-Cotton)

•Composition: A mix of polyester and cotton fibers.

•Features: Combines the durability of polyester with the softness and breathability of cotton.

• Application: Used for shirts, uniforms, casual wear, and sportswear.

B. Nylon-Cotton Fabric (Nylon-Cotton, NC Fabric)

• Composition: Nylon for high strength and abrasion resistance, cotton for softness and comfort.

• Features: Lightweight, tear-resistant, and moisture-wicking.

• Application: Ideal for military uniforms, outdoor jackets, and tactical gear.

C. Polyester-Nylon-Cotton Fabric (TNC Fabric)

• Composition: A hybrid of polyester, nylon, and cotton for superior strength, water resistance, and breathability.

•Features: Offers a balanced blend of durability and comfort with excellent wear resistance.

• Application: Perfect for jackets, workwear, and windproof outerwear.

D. Ultra-Fine Denier Fabrics

•Composition: Made from extremely fine synthetic fibers for a soft and smooth texture.

• Features: Lightweight, highly breathable, and luxurious to the touch.

• Application: Used in premium fashion garments, high-end sportswear, and lightweight outerwear.

4. Key Advantages of Interwoven Fabric

Interwoven fabrics provide numerous advantages, making them ideal for both fashion and functional applications.

A. Strength and Durability

• The combination of synthetic and natural fibers increases fabric longevity.

•Resistant to tearing, abrasion, and frequent washing, making it ideal for workwear and outdoor apparel.

B. Enhanced Comfort and Softness

•Cotton fibers add breathability and moisture absorption, keeping the wearer cool.

•Some blends include spandex for extra stretch and comfort.

C. Moisture Management and Breathability

•Polyester and nylon help wick away moisture, preventing sweat buildup.

•Ensures quick drying, making it suitable for sports and outdoor wear.

D. Wrinkle and Shrink Resistance

•Blends with polyester or nylon are less likely to wrinkle or shrink compared to pure cotton fabrics.

•Easy to maintain, requiring minimal ironing.

E. Versatile Texture and Appearance

•Interwoven fabrics can have a smooth, matte, or glossy finish, depending on the weave and fiber combination.

• Suitable for both casual and formal clothing.

5. Applications of Interwoven Fabric

Interwoven fabrics are widely used across various industries due to their adaptability and high performance.

A. Jackets and Outerwear

• Used for windproof and water-resistant jackets, bomber jackets, and outdoor coats.

• Offers a stylish appearance with functional benefits.

B. Workwear and Uniforms

• Durable and resistant to wear, making it ideal for industrial uniforms, protective clothing, and military gear.

• Provides a balance of comfort and professional appearance.

C. Sportswear and Activewear

•Moisture-wicking and breathable, ensuring comfort during physical activities.

• Used in training gear, sweat-wicking shirts, and lightweight running jackets.

D. Casual and Fashion Wear

• Commonly used for stylish blazers, chinos, and hybrid-texture apparel.

• Enhances durability without compromising on aesthetics.

E. Luggage and Accessories

•Some interwoven fabrics are reinforced for bags, backpacks, and outdoor gear.

• Provides tear resistance and long-term durability.

6. How to Care for Interwoven Fabrics?

To maintain the quality and performance of interwoven fabrics, follow these care tips:

• Machine wash in cold or lukewarm water to prevent fiber damage.

•Use mild detergents to avoid fabric weakening.

•Avoid excessive heat drying, as it can affect the synthetic fibers in the blend.

•Iron at a low to medium temperature, if necessary, to preserve texture and shape.

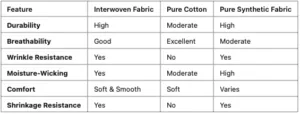

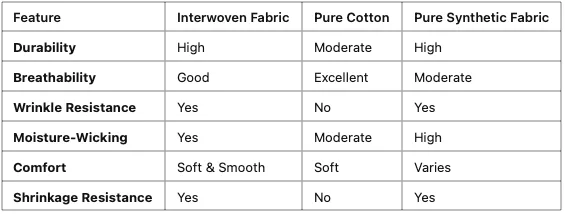

7. Interwoven Fabric vs. Pure Cotton or Synthetic Fabrics

Conclusion

Interwoven fabrics are an excellent choice for garments and textiles that require a combination of durability, comfort, and functionality. Their unique fiber composition ensures optimal performance in both casual and high-performance applications.

Leading textile manufacturers such as fabrics-fty.com and textile-fty.com offer a wide selection of polyester-cotton, nylon-cotton, and TNC fabrics tailored for jackets, workwear, and fashion apparel. With their enhanced properties, these fabrics continue to be a preferred choice in the fashion, sports, and industrial sectors.

#InterwovenFabric #HybridTextile #PolyCotton #NylonCotton #Workwear #OutdoorJackets #PerformanceWear #fabricsfty #textilefty #WindproofFabric