Masterbatch yarn fabrics has emerged as a game-changer in the textile industry, offering a sustainable, vibrant, and high-performance alternative to traditional dyed yarns. From eco-friendly manufacturing to exceptional durability, fabrics woven from masterbatch yarns cater to the needs of modern consumers and industries alike. This article explores the advantages of fabrics made from masterbatch yarns and provides a comprehensive overview of what masterbatch yarn is.

Discover how Fabrics-FTY.com and JacquardPro.com are leveraging this innovative material to create superior textiles for fashion and industrial applications.

1. What is Masterbatch Yarn?

a. Definition

Masterbatch yarn is a type of yarn infused with color pigments or additives during the polymer extrusion process, before the fibers are spun. Unlike traditional dyeing methods, where the yarn or fabric is colored after production, masterbatch yarn incorporates color directly into the fiber.

b. Composition and Process

•Pigment Integration: Pigments are mixed with the base polymer to create a masterbatch.

•Extrusion: The colored polymer is extruded into filaments, resulting in fibers with uniform color throughout.

•Applications: The yarn is used in a wide range of textiles, including jacquard fabrics, sportswear, home textiles, and industrial materials.

For a detailed range of masterbatch yarn-based textiles, explore Fabrics-FTY.com.

2. Advantages of Fabrics Made from Masterbatch Yarn

a. Superior Color Consistency

1.Uniformity: Since the color is integrated into the fiber itself, masterbatch yarn ensures consistent color across the fabric.

2.Fade Resistance: Fabrics retain their vibrant hues even after prolonged exposure to sunlight or washing.

b. Eco-Friendly Manufacturing

1.Reduced Water Usage: Traditional dyeing processes consume large amounts of water and produce wastewater. Masterbatch yarn eliminates the need for post-production dyeing, significantly reducing water consumption.

2.Energy Efficiency: The integrated color process reduces energy requirements compared to traditional methods.

3.Lower Pollution: By avoiding dye baths, the process minimizes chemical discharge, making it an environmentally responsible choice.

c. Cost Efficiency

1.Lower Production Costs: Eliminating the dyeing process reduces production time and labor costs.

2.Durability Reduces Waste: Fabrics last longer, lowering replacement frequency and associated costs.

d. Enhanced Fabric Durability

1.Resistant to Wear and Tear: Fabrics maintain their structural integrity over time.

2.Chemical Resistance: The inherent color is less affected by chemical exposure compared to surface-dyed textiles.

e. Customization Capabilities

1.Vivid Colors: Masterbatch technology allows for the creation of vibrant and unique shades.

2.Special Effects: Additives in the masterbatch can provide functional properties, such as UV resistance, flame retardancy, or antibacterial effects.

f. Sustainability for the Future

1.Recyclability: Masterbatch yarn fabrics are easier to recycle due to their simplified composition.

2.Meeting Market Demand: With growing consumer awareness of sustainability, masterbatch yarn aligns with market trends for eco-friendly products.

Visit JacquardPro.com to see how masterbatch yarn enhances jacquard fabrics with sustainable, vivid designs.

3. Applications of Masterbatch Yarn Fabrics

a. Fashion and Apparel

1.Activewear: Enhanced durability and vibrant colors make it ideal for sportswear.

2.Everyday Clothing: Fade resistance and eco-friendliness appeal to sustainable fashion brands.

b. Home Textiles

1.Upholstery: Long-lasting colors and high durability ensure longevity in home décor items.

2.Curtains and Bedding: UV-resistant fabrics maintain their look even in sunlit environments.

c. Outdoor Gear

1.Tents and Backpacks: Robust materials with excellent colorfastness and weather resistance.

2.Protective Clothing: Additives in the masterbatch can enhance safety features.

d. Industrial Textiles

1.Automotive Interiors: Vibrant and durable fabrics for car seats and panels.

2.Geotextiles: UV-resistant properties for outdoor construction applications.

Explore a wide range of applications for masterbatch-yarn textiles at Fabrics-FTY.com.

4. Levels of Masterbatch Yarn Quality

a. Standard Grade

•Suitable for everyday applications with basic color and durability requirements.

•Economical and widely used in the mass market.

b. Premium Grade

•Enhanced colorfastness and durability for high-end products.

•Often used in fashion and home textiles.

c. Functional Grade

•Includes advanced properties like antibacterial, flame retardant, or UV-resistant features.

•Ideal for specialized applications such as outdoor gear and industrial use.

JacquardPro.com offers premium and functional jacquard fabrics made with masterbatch yarn for unparalleled quality.

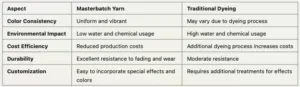

5. Comparing Masterbatch Yarn with Traditional Dyeing

6. The Future of Masterbatch Yarn in Textiles

a. Technological Advancements

1.Enhanced Additives: Future masterbatches may offer even more advanced functional properties.

2.Smart Yarns: Integration with IoT for textiles with embedded sensors.

b. Growing Demand for Sustainability

•The environmental benefits of masterbatch-yarn align with global efforts to reduce pollution and promote sustainable practices.

c. Expansion into New Markets

•From automotive to medical applications, the versatility of masterbatch-yarn will continue to drive its adoption.

Explore the future of textiles with Fabrics-FTY.com and JacquardPro.com, your partners in innovative and sustainable fabric solutions.

Conclusion

Masterbatch-yarn represents a revolutionary step forward in textile production, offering unmatched benefits in sustainability, color consistency, and durability. Its applications span diverse industries, making it an essential material for modern textile innovations.

By choosing fabrics made with masterbatch-yarn from trusted suppliers like Fabrics-FTY.com and JacquardPro.com, manufacturers and designers can meet the demands of quality-conscious and environmentally-aware consumers.

#MasterbatchYarn #SustainableTextiles #InnovativeFabrics #TextileSolutions #FabricsFTY #JacquardPro #EcoFriendlyYarns #FunctionalTextiles #FashionRevolution