In the textile industry, ensuring fabric durability and hygiene is a constant challenge, particularly in humid and warm environments where mold and mildew thrive. Anti-mold and anti-mildew finishing not only extends the life of textiles but also enhances their usability across various applications, from clothing and upholstery to industrial materials. This article explores the principles, methods, and applications of anti-mold and anti-mildew treatments in fabrics, with insights into advanced techniques and sustainable practices.

Understanding Mold and Mildew in Fabrics

What Are Mold and Mildew?

Mold and mildew are fungi that grow on organic materials, including natural textiles such as cotton, wool, and silk. These microorganisms thrive in damp, poorly ventilated conditions, feeding on the cellulose or protein fibers in the fabric. Over time, they cause discoloration, odor, and fiber degradation, reducing the textile’s value and usability.

Why Is Anti-Mold Finishing Important?

1.Extended Fabric Lifespan: Mold and mildew weaken fabric structure, leading to tears and wear. Anti-mold finishes help maintain the fabric’s integrity.

2.Improved Hygiene: Mold can cause allergies and respiratory issues in sensitive individuals. Treated fabrics ensure a safer, healthier environment.

3.Increased Versatility: Anti-mold properties enable fabrics to be used in high-humidity environments such as bathrooms, kitchens, and outdoor settings.

Principles of Anti-Mold and Anti-Mildew Finishing

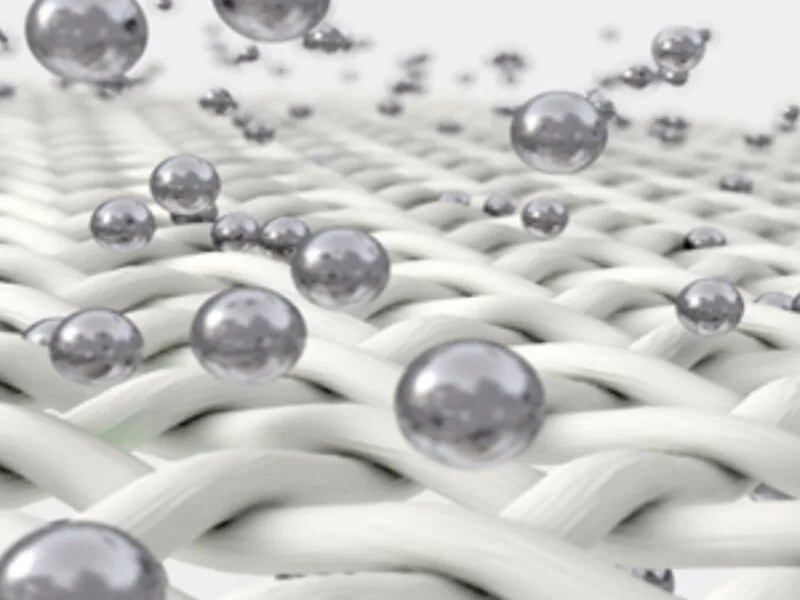

Anti-mold treatments rely on chemical and mechanical processes to prevent fungal growth. The goal is to create an environment on the fabric surface that inhibits fungal colonization without compromising the fabric’s quality or aesthetics.

1.Chemical Finishes / Anti-Mold and Anti-Mildew Finishing

Chemical agents such as fungicides, biocides, and antimicrobial compounds are applied to fabrics to kill or inhibit mold and mildew. These finishes are typically durable, withstanding multiple washes.

•Common Chemicals: Silver nanoparticles, zinc pyrithione, and organosilanes.

•Application Methods: Padding, exhaustion, or spraying.

2.Mechanical Treatments/ Anti-Mold and Anti-Mildew Finishing

Mechanical processes, such as calendaring or heat setting, alter the fabric’s surface properties to make it less conducive to fungal growth.

3.Hybrid Approaches/ Anti-Mold and Anti-Mildew Finishing

A combination of chemical and mechanical treatments often yields the best results, ensuring both durability and efficacy.

Techniques for Anti-Mold and Anti-Mildew Finishing

1.Padding Method/ Anti-Mold and Anti-Mildew Finishing

The fabric is dipped into a chemical solution and then passed through rollers to evenly distribute the treatment. This method ensures uniform application and is commonly used for large-scale production.

2.Exhaustion Method/ Anti-Mold and Anti-Mildew Finishing

In this method, the fabric is immersed in a chemical bath and agitated to allow maximum absorption. The treatment penetrates the fibers, offering long-lasting protection.

3.Spray Application/ Anti-Mold and Anti-Mildew Finishing

Ideal for smaller batches or targeted areas, spraying applies a controlled amount of anti-mold solution to the fabric surface.

4.Microencapsulation/ Anti-Mold and Anti-Mildew Finishing

Advanced microencapsulation techniques encapsulate antimicrobial agents in tiny shells, which are then applied to the fabric. These agents are released gradually, offering sustained protection.

5.Plasma Treatment/ Anti-Mold and Anti-Mildew Finishing

Plasma technology modifies the surface of textiles at the molecular level, improving their resistance to microbial growth without using chemicals.

6.UV Treatment/ Anti-Mold and Anti-Mildew Finishing

UV irradiation sterilizes the fabric surface and enhances the adhesion of anti-microbial coatings.

Applications of Anti-Mold Fabrics

1.Apparel

Anti-mold treatments are widely used in sportswear, outdoor gear, and uniforms to maintain hygiene and durability.

2.Home Textiles

Curtains, upholstery, and bed linens benefit from anti-mold finishes, especially in humid climates.

3.Industrial Textiles

Anti-mold fabrics are used in automotive interiors, marine textiles, and construction materials to prevent degradation in challenging environments.

4.Medical Textiles

Hospital curtains, surgical gowns, and bedding require anti-mold properties to ensure sterility and safety.

Sustainability in Anti-Mold Treatments

With increasing awareness of environmental impact, sustainable anti-mold finishing methods are gaining traction. Leading manufacturers, including those showcased on fabrics-fty.com and textile-fty.com, emphasize eco-friendly processes. These include:

1.Green Chemicals: Using biodegradable and non-toxic antimicrobial agents.

2.Water-Efficient Processes: Adopting techniques that reduce water consumption during application.

3.Recyclable Textiles: Designing fabrics with finishes that do not hinder recyclability.

Challenges in Anti-Mold and Anti-Mildew Finishing

1.Durability

Maintaining the effectiveness of anti-mold finishes after repeated washes or exposure to harsh conditions remains a challenge. Advanced research is focused on developing more durable coatings.

2.Cost

High-quality anti-mold treatments can be costly, making them less accessible for budget-conscious manufacturers.

3.Environmental Impact

Some traditional chemicals used in anti-mold finishes may pose environmental risks. Innovations in sustainable finishes aim to address this issue.

4.Compatibility

The treatment must not compromise the fabric’s hand feel, breathability, or appearance.

Choosing the Right Anti-Mold Fabrics

When selecting anti-mold fabrics, consider the following factors:

1.Application Needs: Choose fabrics with the appropriate level of anti-mold protection based on their intended use.

2.Quality Standards: Ensure the fabrics meet industry standards for antimicrobial efficacy and safety.

3.Reliable Suppliers: Partner with trusted manufacturers like those on fabrics-fty.com and textile-fty.com for high-quality, professionally treated textiles.

Conclusion

Anti-mold and anti-mildew finishing is a crucial aspect of modern textile production, ensuring fabrics remain durable, hygienic, and versatile. From advanced chemical treatments to sustainable solutions, the industry continues to evolve, offering innovative methods to meet consumer and environmental demands. For high-quality anti-mold fabrics tailored to your specific needs, visit fabrics-fty.com or textile-fty.com for a wide range of options.

Keywords: AntiMoldFabrics MildewResistantTextiles FabricDurability EcoFriendlyFinishes AntimicrobialTextiles TextileInnovation SustainableFashion FabricTreatment HomeTextiles IndustrialFabrics