Color Fastness Issues :Polyester-nylon-cotton (T/C/N) fabrics combine the strength of polyester, the durability of nylon, and the comfort of cotton, making them widely used in casual wear, uniforms, outdoor gear, and industrial textiles. However, one of the biggest challenges with these blended fabrics is color fastness—the ability of the fabric to retain its original color when exposed to washing, rubbing, sweat, light, and other external factors.

Color fastness issues not only affect the appearance and lifespan of the fabric but also impact customer satisfaction and brand reputation. Manufacturers and textile suppliers, such as fabrics-fty.com and textile-fty.com, are continuously working to enhance dyeing techniques and finishing treatments to improve color stability.

This article will analyze the causes of color fastness issues in polyester-nylon-cotton fabrics and provide practical solutions to improve dye retention and durability.

1. Understanding Color Fastness in Polyester-Nylon-Cotton Fabrics

Color fastness refers to how well a fabric retains its color under various conditions, such as:

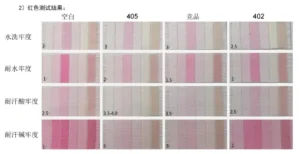

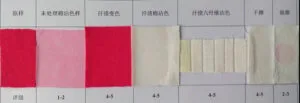

✔ Washing fastness – Resistance to color fading or bleeding after laundering

✔ Rubbing fastness – Color resistance to friction, both dry and wet

✔ Sweat fastness – Reaction to acidic or alkaline sweat

✔ Light fastness – Color resistance when exposed to sunlight

✔ Ironing fastness – Resistance to heat and steam

Due to the different dye absorption properties of polyester, nylon, and cotton, achieving uniform and stable color fastness in T/C/N fabrics can be challenging.

2. Causes of Poor Color Fastness in T/C/N Fabrics

A. Differences in Dye Affinity

Each fiber in the blend has different dyeing requirements:

•Polyester requires disperse dyes and high-temperature dyeing.

• Nylon is dyed using acid or metal-complex dyes.

• Cotton absorbs reactive or direct dyes.

When these fibers are blended, their different dyeing temperatures, chemical reactions, and fixation rates can lead to uneven dyeing, poor fixation, and color fading.

B. Incomplete Fixation of Dyes

•Some dyes may not fully bond with the fibers, leading to easy washing out.

• Poor fixation can be due to low dye concentration, inadequate fixing agents, or improper finishing treatments.

C. pH Imbalance During Dyeing

•Cotton prefers alkaline dye baths, whereas nylon requires an acidic environment.

• A pH imbalance can lead to unstable dye absorption, causing patchy or weak coloration.

D. Low-Quality or Incompatible Dyes

•Using low-quality dyes that lack strong molecular bonding can result in fading after a few washes.

•Incompatible dye selections may react with each other, reducing the overall fastness of the fabric.

E. Inadequate Post-Dyeing Treatments

• Insufficient washing after dyeing can leave residual unfixed dyes, leading to color bleeding.

• Lack of proper fixatives or UV stabilizers can result in poor resistance to light and washing.

3. Solutions to Improve Color Fastness in Polyester-Nylon-Cotton Fabrics

To enhance color fastness and ensure that T/C/N fabrics maintain vibrant and long-lasting colors, manufacturers can adopt the following solutions:

A. Optimizing Dye Selection and Process

✔ Choose compatible dyes: Using a combination of disperse, reactive, and acid dyes ensures better color uniformity.

✔ Use high-quality dyes: Branded and tested dyes with proven fastness ratings help prevent fading.

✔ Adjust dyeing temperature and pH: Carefully control temperature, pH balance, and dye concentration for each fiber type.

B. Enhancing Fixation Techniques

✔ Pre-treatment for better dye absorption: Applying cationic treatments improves dye uptake for nylon and cotton components.

✔ Use crosslinking agents: Special fixatives can strengthen dye-fiber bonding and reduce color bleeding.

✔ Proper washing after dyeing: Ensure all excess dyes are removed to prevent post-dye migration.

C. Applying Advanced Finishing Treatments

✔ Resin finishing: Strengthens the fabric structure, reducing color loss.

✔ UV protection coatings: Helps maintain color brilliance under sunlight.

✔ Anti-fading agents: Helps retain color vibrancy even after multiple washes.

D. Improving Manufacturing Processes

✔ Upgrade dyeing machinery: Using high-efficiency dyeing equipment ensures uniform color penetration.

✔ Implement stricter quality control: Regular testing for washing, rubbing, and light fastness helps detect potential problems early.

4. Advanced Functional Treatments for Color Fastness

Apart from dyeing and fixation improvements, additional functional treatments can enhance fabric performance:

✔ Nano-Coating Technology – Forms a protective barrier against UV rays, stains, and chemical exposure.

✔ Moisture-Wicking Treatment – Prevents sweat-related fading, ideal for sportswear and uniforms.

✔ Anti-Pilling Finishing – Ensures fabric surface remains smooth and vibrant even after repeated wear.

5. Applications of Polyester-Nylon-Cotton Fabrics with Enhanced Color Fastness

With proper dyeing and finishing techniques, T/C/N fabrics with improved color fastness can be used in:

A. Fashion and Apparel

✔ High-end shirts, dresses, and workwear

✔ Sportswear with UV and sweat resistance

✔ Outdoor clothing resistant to sunlight and moisture

B. Uniforms and Workwear

✔ School uniforms that withstand frequent washing

✔ Industrial uniforms with enhanced durability

✔ Military textiles requiring extreme color stability

C. Home Textiles and Upholstery

✔ Curtains, sofa covers, and bedding that retain color after multiple washes

✔ Hotel linens with long-lasting brightness

6. Testing Standards for Color Fastness

To ensure high-quality performance, fabrics should meet international color fastness standards:

✔ ISO 105 – International standard for various fastness tests

✔ AATCC 61 – Washing fastness test

✔ AATCC 116 – Light fastness test

✔ GB/T 5713 – China national standard for color fastness

By following these standards, manufacturers like fabrics-fty.com and textile-fty.com can ensure their polyester-nylon-cotton fabrics meet global textile quality requirements.

Conclusion

Color fastness remains a critical factor in determining the quality and durability of polyester-nylon-cotton fabrics. By understanding the causes of fading and applying advanced dyeing, fixation, and finishing techniques, manufacturers can significantly improve color retention.

Leading textile suppliers such as fabrics-fty.com and textile-fty.com continue to innovate functional and color-stable textiles, ensuring their fabrics meet modern performance demands.

#ColorFastness #TextileDyeing #FabricDurability #FunctionalTextiles #TCNFabrics #HighPerformanceTextiles #IndustrialFabrics #SustainableDyeing #AdvancedTextileFinishing #fabricsfty